12-May-2025

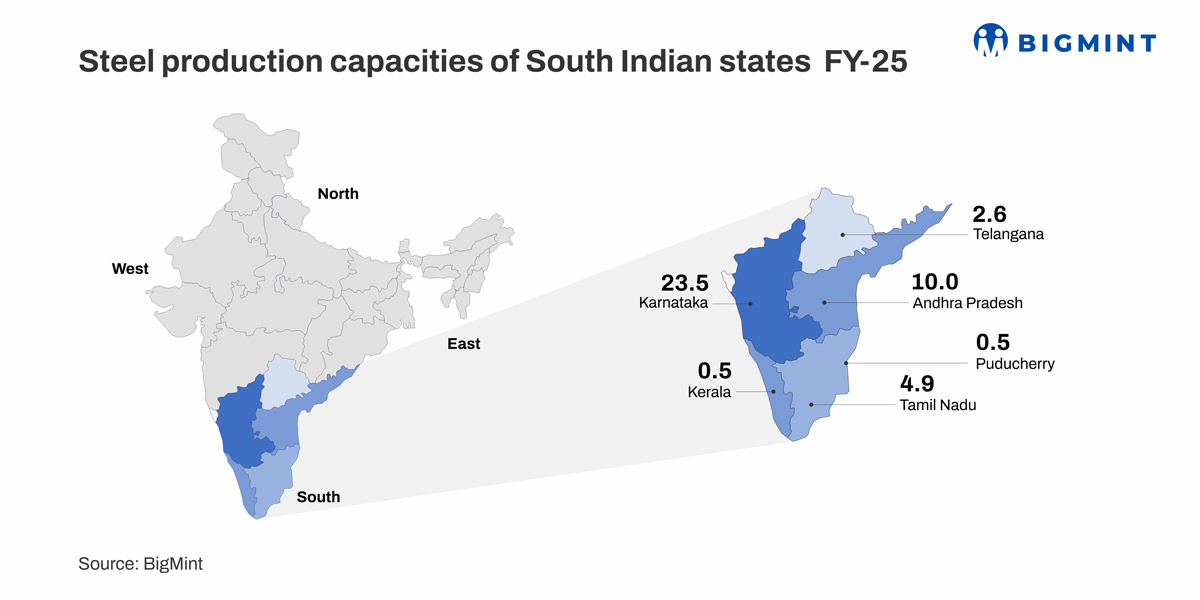

- South Indian states have around 42 mnt of steelmaking capacity

- Region has the highest per capita steel consumption in India

In south India, the secondary steel sector is crucial to the production of a wide range of steel products, especially when it comes to the utilization of sponge iron and scrap steel as raw materials. These raw materials are melted and processed into completed steel products in electric arc furnaces (EAF) and induction furnaces (IF).

Product Types :

- Long steel products: These consist of structural steel, TMT bars, rods, angles, channels, and beams. Construction, infrastructure, engineering, and rail roads are among the industries that use these products.

- Flat steel products: Products such as coils, sheets, and plates made by certain secondary steel plants are utilized in the engineering, automotive, and appliance industries.

- Specialty steel products: A few secondary steel mills in south India concentrate on creating alloy steel, stainless steel, and high-strength steel for specific uses in heavy manufacturing, engineering, automotive, and defence sectors.

Raw material sourcing:

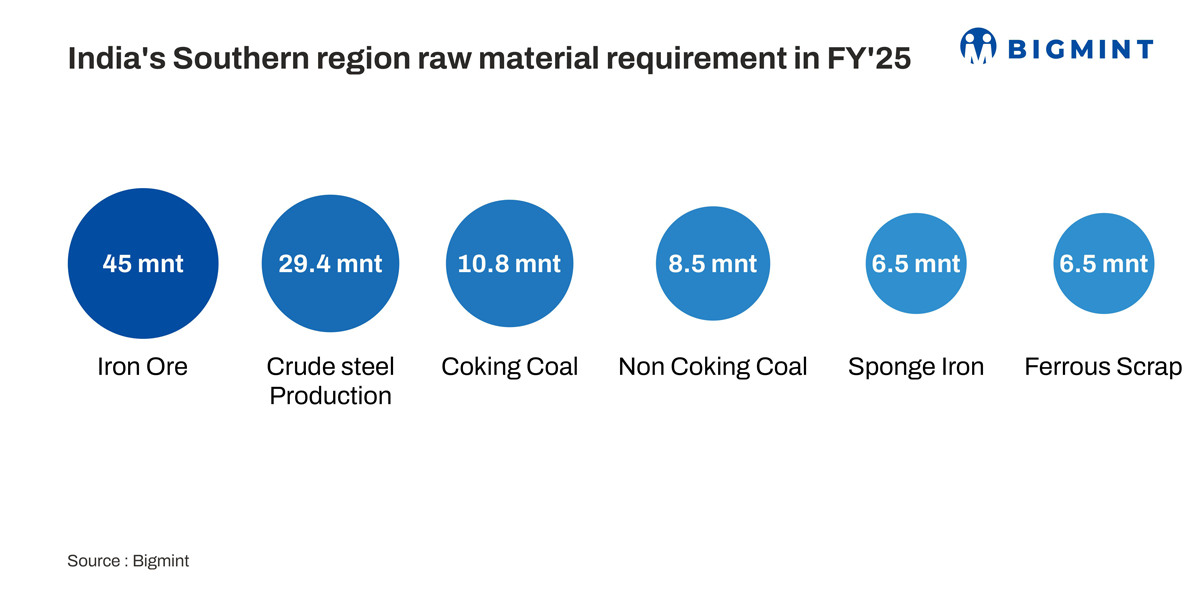

Sourcing raw materials for steel production in South India involves several key elementsprimarily iron ore, coal (coking and non-coking), limestone, ferro alloys and scrap. Here's a breakdown of how and where these materials are typically sourced in and around south India:

Iron ore: Iron ore is the primary raw material for the steelmaking process. Bellary, Chitradurga, and Tumakuru, located in Karnataka, are the primary mining districts that have high-grade hematite ore. There are also major producers like NMDC Donimalai, JSW, MSPL, Vedanta and other private miners in Karnataka. Around 46 Mnt of iron ore was produced in FY25 in Karnataka while consumption stood at around 33 Mnt. Andhra Pradesh, too, has a few mines that supply local steel producers and cater to the export market through Krishnapatnam port.

Coking coal: Since south India has no significant reserves of coking coal, the region relies heavily on imports from Australia, the US, Canada, and Indonesia, mostly PCI, through importing ports like Vizag , Ennore, Krishnapatnam, and Mangalore. Domestic coking coal mainly comes from Jharkhand and West Bengal (Bokaro, Dhanbad), transported by rail or sea. Around 89 Mnt of coal/coke were imported via the different ports in south India in FY25.

Limestone and dolomite: These are used primarily as fluxing agents in blast furnaces and for steel refining. South India is well-endowed with reserves of both, and they are actively mined and supplied to steel plants and other industries.

Manganese ore: It is an alloying agent used to improve the hardness and durability of steel. While south India is not the largest producer of manganese in India, it does have significant reserves and mining activity, particularly in Karnataka and Andhra Pradesh. Sandur Manganese & Iron Ores Ltd. (SMIORE), a prominent mining and ferroalloys producer in Karnataka has manganese ore production capacity of around in 0.5 Mnt and produced around 0.37 Mnt in the last FY.

Sponge iron: Karnataka is a significant hub for Direct Reduced Iron (DRI) or sponge iron production in India, with several plants operating across the state. The installed capacity in Karnataka is around 5.36 MnT which produced 87% of total capacity, around 4.65 MnT last fiscal. Overall production capacity in south India is around 8.13 MnT.

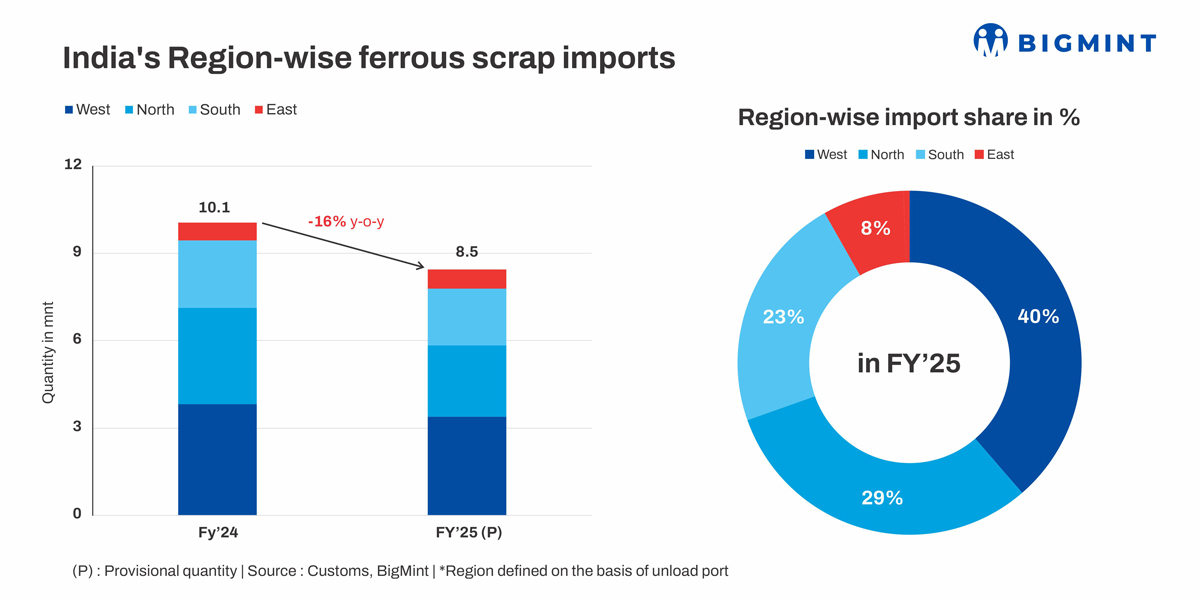

Melting scrap: Chennai serves as a significant hub for scrap metal recycling, particularly for melting scrap used in steel production like heavy melting scrap, turning and boring, shredded, plate and structural, etc. Chennai hosts several steel plants and foundries that utilise melting scrap for production. These facilities typically employ Electric Arc Furnaces (EAFs) or Induction Furnaces for melting scrap metal, depending on their capacity and the type of metal being processed. Around 2.8 Mnt of ferrous scrap was consumed by steel industries located in Chennai and overall 5.8 Mnt in south India in the last fiscal.

Per capita steel consumption:

India's overall per capita steel consumption is estimated to be approximately 97.7 kg, with projections aiming to increase this to 160 kg by 2030-31 under the National Steel Policy. The southern states, particularly Telangana and Andhra Pradesh, are expected to play a pivotal role in achieving this target due to their ongoing infrastructure and industrial developments.

Join us at FUTURE.STEEL SOUTH, taking place on 18-19 June 2025 at Taj Coromandel, Chennai the Southern hub of India's accelerating steel ecosystem. With South India contributing ~27 million tonnes of steel output, this region is fast emerging as a strategic pillar of India's steel growth story.

BigMint proudly brings its flagship steel conference to Chennai, featuring 30+ expert speakers across 7+ insightful sessions. This edition will offer an in-depth exploration of key themes including Pricing, Policy, Trade, and Technology, alongside crucial discussions on Green Steel, Scrap, Sustainability, Outlook, Indexing, and Capacity Expansion.

Attendees can look forward to unmatched opportunities in Sponsorships, Exhibition Stalls, and over 10 hours of high-impact networking with leading steel producers, buyers, traders, technology providers, miners, end users, and policymakers. An exclusive Steel Plant Tour is also scheduled for 19 June, offering firsthand industry insights.

Don't miss South India's most strategic steel dialogue secure your spot now: https://tinyurl.com/33985dkn